Who are we?

WESCAN Field Resources provides Field and Site Management and Consultation for electrical installation in the Commercial, Institutional, Industrial and Transmission & Distribution fields on a contractual basis. Our electrical expertise over the last 45 years covers a wide range from ultra-low DC control voltages to 500,000 volts AC Transmission Services. Our experience spans providing high level low voltage electronic security services for Government Agencies to GREEN Technology Tidal Waters Submersed Turbine Generator Metering Stations to Breaker Replacement of 500KV/2000A with new Siemens 500KV/4200A Breakers and controls within a live BROWN FIELD, to Pumping Station Replacement on the TransCanada Pipeline and complete replacement of two 160 KV Substations SIMULTANEOUSLY while managing the Hydro Line Crews as well as many, many more scenarios, many being on Indigenous Lands, such as the site below.

On ALL sites, our main goals are Safety first, complete Communication with all involved, On-time supply and completion of the project on time and on budget. As safety is a main requirement on our sites, tidiness is mandatory. All contractors and sub-contractors must submit a SAFE WORK PLAN, including housekeeping, to both the PRINCIPAL and WESCAN prior to mobilization onto the site. Upon agreement with the PRINCIPLE, WESCAN may provide the logistics of the project as well.

WE OFFER:

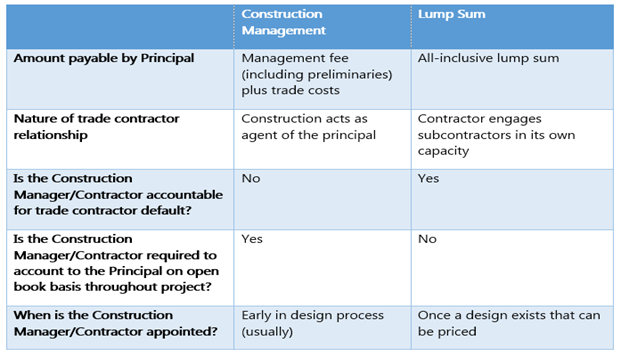

No task is too small or project too large. As a Construction Manager, the PRINCIPAL remains in control, unlike in a LUMP SUM Contract. WESCAN, as representative agent, will carry out the requirements of the PRINCIPAL in contractually agreed upon tasks.

While acting as the AGENT, WESCAN will honor a fiduciary obligation to the PRINCIPAL and endeavor to act transparent and always in the PRINCIPAL’s best interest. Within our standard agreement we will maintain a hands-on relationship with all multi-trade contractors and sub-contractors and suppliers, private or indigenous landowners, regulatory agencies and environmental agencies.

Where the project may impact the community or businesses and can be of particular interest to the Media or Political stakeholders, WESCAN may promote it’s benefits. Although these types of communications usually are thought of as Managing damage control in cases of incident, communication management can also provide good news about the project.

Mobilization

Under our Early Contractor Involvement, WESCAN will set the parameters of site mobilization, materials deliveries and receiving, taking into account the Lead times in procurement of PRINCIPAL supplied equipment and supplies in the schedule provided, warehousing and construction process procedures. With the various trades and subtrades we will chair the startup and weekly progress meetings and attend all daily safety meetings.

We will Audit all work as it proceeds, to ensure proper construction methods and quality controls are being applied, handle all engineered drawings, Inspection reports, Requests for Information (RFI), Request for Change (RFC), Request for Payment (RFP), Field Memos (FM), Change Orders Requests (COR), Change Orders (CO), Non-Compliance Orders (NCO), Utilities Interface, Community Relations and Punch lists as well as monitor and investigate all safety issues along the way. Completion or Partial Completion certificates may be offered and presented along with those payments.

Commissioning

We will initiate a Commissioning plan as a part of, or a complimentary document to, the Project Management Plan. Advance planning of the Commissioning process can and does reduce the risks of prolonging the project in its last stage by outlining the roles and responsibilities of each group involved and that they fully understand the commissioning plan. At this point all Operation and Maintenance Manuals are available, validated accepted as checked and true and accurate.We will assure System Coordination throughout the integration testing by developing and implementing a Safety and Security Certification Plan contingent for emergencies in close coordination Emergency Responders within the area.

Figure 7-2 – Typical Equipment Commissioning List (sample only)

| LEED® | ITEM | HVAC System (and all integral equipment controls): |

| X | 1. | Pumps (chilled water) if required |

| X | 2. | Chillers if required |

| X | 3. | Piping, cleaning, and purging |

| X | 4. | Chemical treatment |

| X | 5. | Ductwork |

| X | 6. | Air handling units |

| X | 7. | Heating/A.C (including controls, piping, pumps, compressors) recovery & ventilating units |

| X | 8. | Split systems |

| X | 9. | Air terminal units |

| X | 120. | Testing, adjusting, and balancing work (TAB) |

| X | 11. | Unit heaters (area, cabinet) |

| X | 12. | Building automation system (controlled devices, control loops, and system integration) |

| X | 13. | Fans & ventilation systems including fume and exhaust evacuation systems |

| X | 14. | Variable frequency drives |

| X | 15. | Humidifiers |

| LEED® | ITEM | Mechanical Systems: (As related to facilities and processes including primary control systems) |

| X | 16. | Building envelope |

| 17. | Overhead roll-up doors and grilles | |

| X | 18. | Boilers |

| 19. | Bus wash and reclamation system | |

| 20. | Elevators (freight and passenger) | |

| 21. | Bulk fluid storage and distribution systems including but not limited to diesel fuel, fuel oil, motor oil, antifreeze, chassis grease, automatic transmission fluid, gear oil, windshield washer fluid, and waste fluids | |

| 22. | Oil/water separator systems | |

| 23. | Paint spray booths | |

| 24. | Compressed air system | |

| 25. | Domestic water system (plumbing, fixtures etc.) | |

| 26. | Piping | |

| 27. | Monorail systems and traveling cranes | |

| LEED® | ITEM | Electrical Systems: |

| X | 28. | Sweep and scheduled lighting controls (i.e. photocells, occupancy sensors) |

| 29. | Fire alarm system | |

| 30. | Emergency power system and transfer switch | |

| X | 31. | UPS |

| 32. | Wiring devices | |

| 33. | Transient voltage suppression | |

| 34. | Secondary unit substations | |

| 35. | Enclosed switches and circuit breakers | |

| 36. | Enclosed controllers | |

| 37. | Panel boards | |

| 38. | Dry-type transformers | |

| 39. | Grounding | |

| 40. | Battery charging system | |

| 41. | Level gauging and leak detection systems for bulk fluid systems and tanks | |

| 42. | Fuel management system | |

| 43. | Bus traffic control system and pedestrian protection system | |

| 44. | Data communications system | |

| 45. | Integrated telephone and paging systems | |

| 46. | Security system | |

| 47. | Closed-circuit television (CCTV) system | |

| 48. | Time clock system | |

| LEED® | ITEM | Life Safety Systems: |

| 49. | Emergency lights and signs | |

| 50. | Emergency eye wash | |

| 51. | Fire protection (including but not limited to fire pump, standpipe, and sprinkler systems) | |

| 52. | Gas detection |

CLOSEOUT

We will, along with the PRINCIPAL and applicable trades, lead a Final Walk Through Inspection of the Facility and create a final punch list of incomplete Contractor items, resolve any outstanding claims, assess and document Lessons Learned, develop a plan for Demobilization, obtain Project acceptance from PRINCIPAL Stakeholders and obtain Certificate of Completion.

Demobilization

WESCAN will remain on site until all waste and unnecessary materials have been removed by the trades and all decommissioning of temporary facilities and equipment have been removed.